What sanding disc is best?

When considering what is the best sanding disc to use for a specific job there is an overwhelming range of different discs, grains and grits available on the market. It is difficult to know what to choose for your job. This article will address the most suitable disc to use depending on your requirements.

Different Sandpaper Grains

Not only does the density of sandpaper grit make a difference in the success of your sanding project, but the type of abrasive material does, too. The following is a brief description of the more common types of abrasive grains used in sandpaper products.

Aluminium Oxide

Aluminium oxide (generally brown in colour), is a durable synthetic grit, is well suited for sanding and polishing various types of metal, including bronze and alloy steel, in addition to being a good choice for sanding all types of woods. Unfortunately this grain is not suitable for work on stainless steel as it is not INOX (iron free) grade. For this reason Smith & ARROW do not sell sanding discs in this grain.

Zirconia Alumina

Zirconium / Zirconia (generally blue/green in colour) is suitable for use on all materials including wood, fiberglass, metal, brass, aluminium, and 125mm 5" Fibre Sanding Discstainless steel – including painted surfaces. Unlike aluminium oxide zirconia can be used on both mild and stainless steel, and will cut faster and last four to five times longer than aluminium oxide discs. This grain is long-lasting and well-suited for grinding away burrs on metal and for an initial sanding of rough wood. When sanding metal with zirconia alumina, the grit particles can actually become sharper, so you won’t have to change sandpaper frequently. Smith & ARROW stock fibre discs and flap discs in this grain type.

Ceramic

Ceramic abrasive grain (generally red in colour) is the top of the range in terms of both effective cutting ability and how long the discs will last. It is extremely tough, sharp, and long-wearing and does not dull quickly because of its extreme density, making it best for aggressive material removal with both wood and all types of metal including Stainless Steel. This makes ceramic discs the best choice for removing stock, and sanding all surfaces in wood or metal. For this reason, ceramic abrasive discs are generally more popular in the more coarse grits. Ceramic abrasives are durable, and lasting longer than both aluminium oxide and zirconia.

Different Sanding Abrasive Discs for Angle Grinders

Fibre Sanding Discs4" 100mm Zirconia Fibre Sanding Discs

Manufactured from an abrasive fibre sandpaper, Fibre Discs are a round disc with a round hole or star pattern in the centre. They are made from a stiff, card–like backing coated in a wide variety of abrasive materials and are generally used with a rubber or polyurethane backing pad on an angle grinder. They are the recommended abrasive wheels for medium to light stock removal on both mild and stainless steel. Used on a backing plate on an angle grinder, resin fibre discs have an extensive scope of applications ranging from fine and coarse sanding, blending welds, deburring and de-rusting. The most common use of fibre sanding discs is for sanding layers of paint, sanding back welds and welding splatter or generally taking work back to bare metal.

Flap Discs

5" 125mm Zirconia Flap Disc

Flap discs are a very popular sanding / grinding product due to their versatility and long lasting design attributes. Applied directly to the angle grinder with no need for a sanding pad, frap discs are cleverly designed for rapid effective removal of stock in most applications. Their design allows for the cutting edge of each flap to fall away cleanly once the abrasive grain has been used up, exposing the fresh face of the new abrasive grain on the flap underneath it. Essentially, flap discs are designed to allow for the abrasive grain to cut effectively for as long as possible and then release cleanly to open up the fresh cutting grain on the flap underneath – providing a more consistent finish and uniform cut rate. Flap discs are one of the best abrasive /grinding wheel for fast stock removal, deburring welds and provide grinding, blending and finishing with one product.

Strip Discs

Poly Strip Disc Rust Paint Removal

The main application for using a “poly strip disc” or “strip disc” is when it is important for the substrate or underlying material is to be left virtually untouched. All other removal tools such as sanding discs, grinding discs and flap discs will remove the wood or steel underneath, for example paint once it has been removed, and damage that surface. The value of using a strip disc in this situation is that it will remove the rust or the paint from the surface without starting to remove the steel, or fiberglass or wood that is underneath. Very popular for use in the auto industry, poly strip discs will remove the paint from car panels in just one pass of the grinder without damaging the metal panel underneath and causing “flat spots”.

Different Sanding Grit Sizes

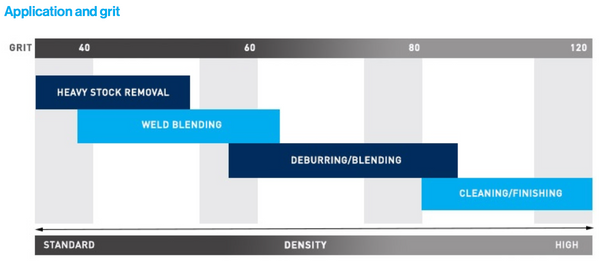

Sandpaper is measured by its grit size, or number of sharp particles per square inch of sandpaper – the lower the grit number, the courser or harsher the grit. A 24 grit sanding product will be very aggressive in the removal of stock leaving harsh scratches on the surface, as opposed to a 600 grit sandpaper which is designed to remove less material in a way that leaves a smoother finish. You need to choose the grit size of sandpaper depending on the particular job you are trying to accomplish. The higher the number, the smaller the grains and the finer the sandpaper grit. Conversely, lower numbers indicate larger grains and overall coarser sandpaper. Many jobs require you to “go through the grits.” This means you start the project using lower numbered grit and use finer pieces of sandpaper as you progress. Each time you advance to a higher grit sandpaper, you remove the scratches from the previous layer. Grit are used as follows:

- 24 grit: Rough stock removal. It is used for grinding back steel or welds as well as removing paint and varnish that you think might never come off.

- 36/40 grit: Aggressive grinding and weld removal (very popular), such as sanding the edge of a sticking door to make it close flush.

- 60 grit: When medium grinding and finishing are required in one step. This grit is a good starting point for most projects involving working with steel or wood.

- 80 grit: Very similar to the 60 grit, 80 grit is just a little less course and a very popular grit for most metalworking jobs.

- 120 grit: A good choice for fine surface blending and finishing in both metal and wood working applications.

- 240 – 400 grit: Extra-fine grit sandpaper is used for light sanding between coats of finish and to sand metal and other hard surfaces

- 600 grit and higher: Super-fine surface finishing / polishing. Ideal to sand the final layer of finish on wood or metal. It is just strong enough to thin patches and small inconsistencies in the layer’s application, but not rough enough to actually remove anything that would want to be kept.

Smith & ARROW stock sanding discs for angle grinders in 24, 36, 40, 60, 80 and 120 grit. If you are seeking an angle grinder sanding disc, Smith & ARROW sells:

- Fibre discs in ceramic and zirconia options. These discs come in 4”, 4.5”, 5” and 7” sizes

- Flap discs in zirconia, sold in 4”, 4.5”, 5” and 7” sizes

- Strip discs sold in 4”, 4.5”, 5” and 7”