What HSS drill bit is best for metal?

How do you choose the right drill bit for the job?

There are three questions to ask when you are choosing a drill bit for a job: How is it made, what material is it made from, what is the design of the cutting tip?

All good drill bits for drilling all types of steel fall under the category HSS or High Speed Steel drill bits.

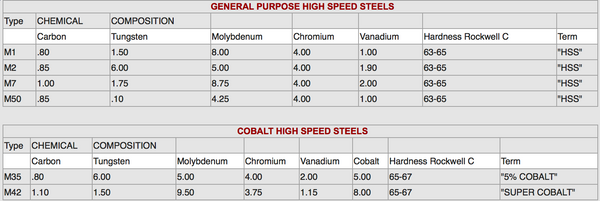

The very best drill bits are “Fully Ground” which means the bit was ground out of the one piece of raw material, and as such are very precise and strong. The table below outlines some of the more popular answers as to the second question: What material are they made from. All of these HSS drill bits are superior to carbon steel in that they can withstand higher temperatures without losing their temper (hardness). This property allows HSS to cut faster, and at room temperature HSS grades generally display high hardness. The types of HSS Steel used in Drill Bits are below:

The Best Drill Bits Comparison Table

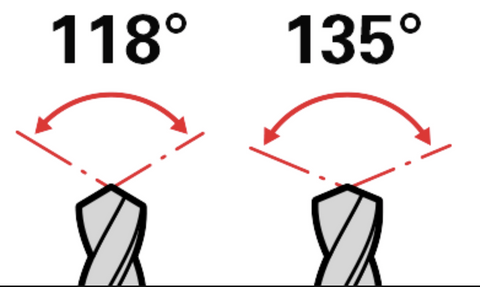

The design of the cutting tip is also very important. Perhaps the most popular tip design has a 135 degree “split point” design giving accurate starting without the use of a center punch.

The Best HSS Bit Depends on your Application

The most popular HSS drill bits fall into the following two categories: M2 & M35. Depending if you are drilling mild steel or hardened steel will determine whether you purchase M2 or M35 drill bits:

M2 DRILL BITS

M2 is a HSS drill bit compound that has high wear resistance and is used in all general steel drilling applications involving standard / mild / black steel. M2 retains its cutting edge longer than other general purpose high speed steel drill bits when working in general steel engineering applications, however, is not as shock resistant or as flexible as other HSS grades with less tungsten. Drill bits made from M2 material are generally favoured for high production machine work.

Pros:

- Are cheaper than M35 bits

- Everyday use for milder steel, plastics, fibreglass, drywall and wood (although a specialised wood bit is better)

- Sharpened easily for long use

- Not brittle, like M35 bits can be if not used at slow speed

Cons:

- Will struggle to drill through any type of hardened steel as no cobalt is added

- Can lose their sharpened edge quicker than cobalt bits

- Will not last as long as M35 cobalt bits

BUY Fully Ground, M2, 135 Degree Split Point Smith & ARROW Drill Bits Here

M35 DRILL BITS

M35 is similar to M2, but with 5% cobalt added – NOTE: M42 is almost the same but with 8% cobalt and is generally considered a very specialised bit and is more brittle than M35. The key purpose of adding up the cobalt is to enhance the heat resistance capacity and durability of the bits, however, it is very important to note that M35 bits work best and last longest if run at slow working speeds with lubricant. Used primarily for drilling Stainless Steel, these bits gain the property of endurance against the high temperature due to cobalt metal.This HSS material was developed to tackle drilling of tough materials like Stainless steel, Inconel, tool steels and titanium alloys.

Pros:

- Will drill through hardened steel like stainless as well as mild steelHSS Twist METRIC Metal Drill Bits, M35 Cobalt (Jobber Bits)

- Cobalt will do everything the M2 bit can do, and more

- Cobalt ensures the bit is heat resistant

- Keeps long lasting cutting edges and will not dull easily

- Can be sharpened relatively easily

- Better than M42 (8% cobalt) as it not brittle like M42

Cons:

- Must be used at a slow speed, as cobalt can make the bit more brittle then M2 bits

- More expensive than M2 HSS bits

Do Coatings Make a Difference?

TiN (Titanium Nitride) coatings can increase the wear resistance and lubricity at the cutting point and facilitate use higher speeds and feeds M2 Metal Step Drill Bit Set: 4mm-12mm, 8 Stepsand improve tool life. TiN coated tools can easily be identified by the characteristic golden colour coating on HSS tools. TiN coating can increase the cost of drills by 30 to 50% depending on size and batch quantity and practically about 30-100% increase in drilling speeds can be applied with coated drills.

All Smith & ARROW Step Drills are M2 HSS bits are TiN (Titanium Nitride) coated.

BUY Smith & ARROW Step Drill Bits Here

Main Considerations when Buying Drill Bits

- How the bit was made – Note: some very cheap drill bits are molded and the material used is so soft the bit will bend under pressure! Fully Ground drill bits are the gold standard in HSS drill bits.

- Material used: As discussed above, material is the essential factor, which affects the selection of your drill bit.135º vs 118º split point drill bit tip

- Length: The durability of the bit also depends on the length. As the length of the bit increases, the durability and toughness of the bit decreases. All in all shorter cobalt bits withstand breaking, spinning and twisting.

- Size: Make sure you get variety in sizes, before purchasing any drill bit set. Availability of different diameters will make your drill machine work for multiple jobs.

- Tip point style: Tip style will determine the penetration capacity of bit through the material. The 135° Quick-Cut points are self-centering and penetrate quickly with less pressure. The 135 degree split point style is most commonly used in cobalt drill bits and are the recommended tip type when drilling steel.

135º Drill Bit Tip is Most Effective

How to Make your Drill Bits Last

Drill bits are destroyed by heat, so:

- Reduce the drill speed,

- Use a coolant/lubricant to prevent friction and drill bit heating. Liquid dishwashing soap (and water) are a good coolant/lubricant for composites that won’t stain.

- Coated drill bits will last longer and don’t cost much more than regular high speed steel.

- If you’re cutting anything deep and/or really big, pull the drill bit out occasionally and brush the chips/dust away. If you’re drilling dry they won’t really gather up (because they get kicked into the air), but if you’re using lube they’ll form a sort of paste that gets in the way.

- Let the bit do the cutting, not pressure. Apply just enough pressure for the bit to work, any more than that and you are dulling the cutting edge of the bit.

Smith & ARROW offers a wide range of metal drill in M2 and M35 steel – all Fully Ground and with a 135 degree split point. We offer individual bits, sets, step drills and double ended drill bits. We also have auger and brad-point drill bits for the woodworking industry, masonry SDS Plus drill bits, and specialised glass / tile drill bits with a unique 4 tip design.